landlockeddivingdoc

Registered

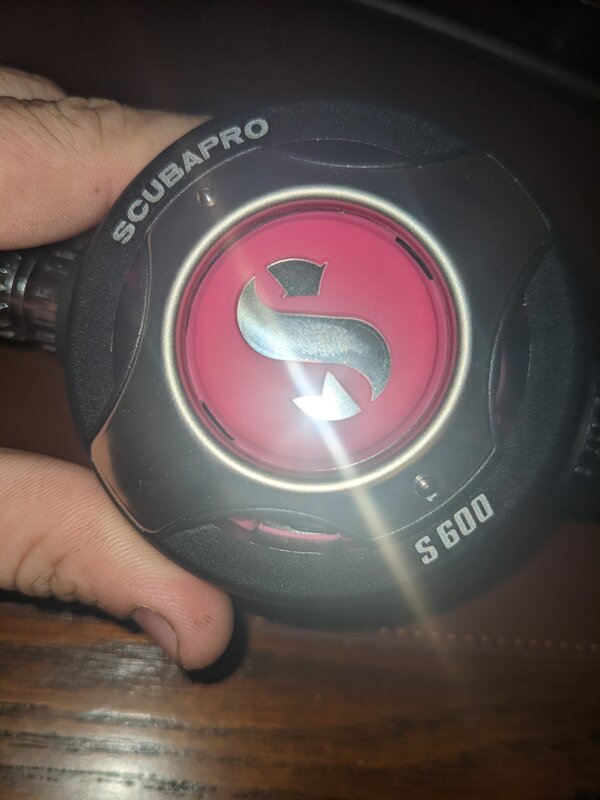

Hi all. At my wife's request, a lot of her gear is getting accessorized in pink... Including her primary, a 4th Gen scubapro s600.

Today I swapped out her mouthpiece easily, and I tried to swap the purge cover, and am running into a problem:

-retaining pin removed without issue

-faceplate/old cover were snug, but not so much that I couldn't twist them off using only my palm

-faceplate, cover, antifriction assembly look fine. Diaphragm looks fine.

-parts were cleaned, dried. New cover placed in faceplate, making sure the little tabs were in their respective places, and cover sat flush.

-parts were reassembled, ensuring no cross threading, and I attempted to screw it down, and this is where I'm getting into trouble: I can't seem (at least with palm pressure) to rotate it the last 1/8 of a turn to get it into alignment/permit replacement of the retaining pin.

Although I'm probably just overthinking this and just need to force it one way or another, I'm reluctant to do this because it looks like the little silicone struts (that run from the button to the base ring) on the purge cover are quite asymmetric at the end of the installation attempt relative to their position in the apertures on the faceplate-the best way that I can describe it if it's not very visible in the picture above (it's quite noticible in person), is that the pink "strut" seems to "drag behind" the chrome struts on the cover as it's being screwed clockwise. and this makes me worried that instead of just compressing, it's being subject to quite a bit of rotational force when being screwed down. ..And I'm worried about the damage or functional implications if that holds true of the diaphragm as well.

What am I missing here? Do I need to just get a tool and force it? Put some christolube on it? Exchange the cover?

Any advice would be greatly appreciated.

Today I swapped out her mouthpiece easily, and I tried to swap the purge cover, and am running into a problem:

-retaining pin removed without issue

-faceplate/old cover were snug, but not so much that I couldn't twist them off using only my palm

-faceplate, cover, antifriction assembly look fine. Diaphragm looks fine.

-parts were cleaned, dried. New cover placed in faceplate, making sure the little tabs were in their respective places, and cover sat flush.

-parts were reassembled, ensuring no cross threading, and I attempted to screw it down, and this is where I'm getting into trouble: I can't seem (at least with palm pressure) to rotate it the last 1/8 of a turn to get it into alignment/permit replacement of the retaining pin.

Although I'm probably just overthinking this and just need to force it one way or another, I'm reluctant to do this because it looks like the little silicone struts (that run from the button to the base ring) on the purge cover are quite asymmetric at the end of the installation attempt relative to their position in the apertures on the faceplate-the best way that I can describe it if it's not very visible in the picture above (it's quite noticible in person), is that the pink "strut" seems to "drag behind" the chrome struts on the cover as it's being screwed clockwise. and this makes me worried that instead of just compressing, it's being subject to quite a bit of rotational force when being screwed down. ..And I'm worried about the damage or functional implications if that holds true of the diaphragm as well.

What am I missing here? Do I need to just get a tool and force it? Put some christolube on it? Exchange the cover?

Any advice would be greatly appreciated.