R

redacted

Guest

Take a look at the tech manual and see if you can figure out how that makes any sense. Perhaps your shop can explain that in the context of a cutaway of those devices.

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

I took a trip to the dive shop that serviced my regulator post failure this afternoon. The service manager was there and he took the time to explain to me why he believes what we have been discussing in this thread could cause the out of air situation. There were 2 things loose on my regulator when I took it to them. The yoke nut and the ACD inner post valve. This caused both the outer cylinder (the part you can push in with your finger) and the fixed inner cylinder have play relative to each other. The combination of looseness of both parts of the ACD were sufficient to allow it to go shut. As he was demonstrating (on a fully assembled regulator) it sure sounded believable to me. Please also understand - this is my translation of the conversation so I may not use terms as accurately as he did. He did stress to me that both pieces have torque specifications and that both need to be torqued to the proper specification.

Your dive shop is a bit scary. A shop tech can perform a routine service on regs without understanding how they work if they follow the instructions. But, when a problem occurrs, it really is quite an advantage to have an understandinf of how the devices function and how they may fail. A loose yoke retainner will eventually leak gas between the body and the retainer.

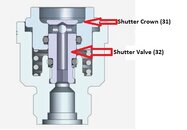

A loose shutter valve will increase the clearance between that valve and the shutter crown, not cause that valve to close and block air supply.

Now, if you told me they found a misplaced o-ring between the yoke retainer and the shutter valve, I could see the reported failure mode. But would have to wonder how it worked without problem for so many dves. Probably not a bad idea to check the movement of that shutter valve crown often.

I have been reading some of this thread and I agree with you.

The only thing that I am wondering is if the Shutter Valve (Item 32) is loose, could it loosen up enough to partially block the tank valve outlet, but otherwise go unnoticed? Not likely, but looking at the manual, I can’t see a failure mode that explains the description of the events.

From my experience with the DIN ACD. If the shutter valve is loose. then you get a leak similar to a missing O ring when you pressurise the system. It only needs to be 1/4 turn. I presume (looking at the drawings) that when correctly tightened the base of the shutter valve provides a seal.

If loose, then the gas escapes around this, past the O ring and out past the shutter.

I'm not certain of the exact process only the fact you get a leak. This 1/4 isn't enough to cause a restriction on the back of the valve, so I presume the fact that it will leak is that it's a designed fail safe.

My point here is that if the Shutter valve were even slightly loose you'd know about it pre dive.

I think it's fair to say that the ACD isn't at fault and that the LDS was wrong with their diagnosis. My guess is that they jumped on two loose items and have decided that was the cause.

NB the shutter valve can become loose over time, caused by the shutter rotating around the valve if there is the slightest pressure in the system. Happens on all 4 on my 1st stages and they've all been correctly torqued by me and the local shop. It's a known if not slightly annoying issue

View attachment 384626

Since AL owns Apeks, can it be done for them too? I would love to get my tech spec, so I can legally service my DST/XTX50 regs.Actually with AL, it's done online. All you need is a credit card to become a authorized technician....

Since AL owns Apeks, can it be done for them too? I would love to get my tech spec, so I can legally service my DST/XTX50 regs.

If positive, would you, please,provide link or instructions how to do that?