SoulSniper

Registered

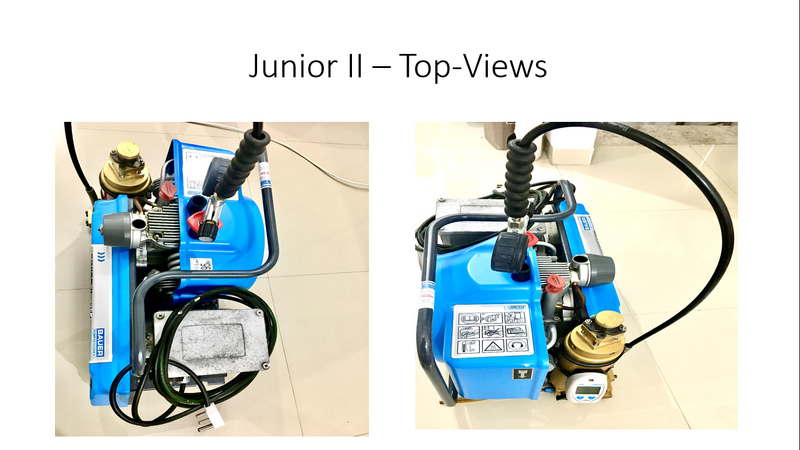

Finally Got my hands on the Bauer Junior II.

Consider this a rookie post, I wanted to share my story that might help prospective buyers not get cheated.

And my buying experience of a pre-owned Bauer Unit.

The Unit is 2016 produced by Bauer, Germany.

It also has an Inspection Label from Dec'2020 carried out by Dolphin Middle East Marine.

This was a used unit, and per the B-Timer installed over it, it says 16hours Only.

After I replaced its cell, it read 17 hours. Does it adds up Hours Count at every Power Source Disconnection Event too (Just thinking)?

We got the Cartridge Changed since the Unit was lying idle since months.

Parts Replaced by new items:

Looked like that from a commercial manufacturing setup.

The Warm Greeting from them, the courtesy they displayed, and they walked us through all the other warehouses too where they had machines of very large capacities besides Breathing Compressors of over 25 cfm, Bauer Old Verticus models ranging 20+ cfm, Huge Refrigeration Compressors, Offshore Welding Equipment, and so on...

The day before, I couldn't settle and decided to clean it all the way I could reach, and opened the body frames (Pictures attached).

So this is a SIngle-Phase 240V 2.2 kW Soga make Motor badged as Bauer Part for the equipment.

To my surprise, the Power Distribution Box (Terminal Box) housing the Start and Run Capacitors, and the relays, had no dust at all in it.

The Terminal Box is some cast-aluminum body with a high density foam liner to prevent any foreign particles get into the electricals.

The Cable is also the Original one too, and just doesn't entangle.

The original Single-Phase Plug-to-Mains Connector was Cut since the Power Supply at the warehouse didn't have compatible socket, they only had for 3-phase mains.

So i got a 16A Plug and have made the connection arrangement.

For the test at the warehouse, we emptied a 6L 300 Bar Drager Cylinder, and refilled it.

The clock after we engaged the valves on Filling device and that on the cylinder, clocked 22.5 minutes to fill up to 310 Bar with 2 manual drain events from each of the drain valves.

Noise is bearable keeping it at one end of room and 10m away doesn't hurt at all.

For less than half the cost of new Junior-II like product in India (with P-11 Filters, PE-100 is available re-named as IE-100), this feels a Steal-Buy.

I verified with Bauer Facility for the Serial Number, Block Parts, commissioning details and everything they could provide non-invasively, and the Unit came out Genuine.

Today i topped-up my other Cylinder from 200 to 300 Bar, took less than 8 minutes, and the noise that the machine makes felt so soothing.

I'm worry free for don't know how many years now, for reliable Machine, this work-horse.

Sharing some pictures from cleaning it.

An important note for Buyers looking for used compressors from Bhavnagar, India (Alang Ship Wrecking Yard):

There are only a handful of Genuine Traders who will charge more than anybody else selling Breathing Compressors, but give the machine in as-is condition from how they were received by them.

The "others" (bad ones) that would quote half or 3/4 of the cost quoted by genuine traders, are all messing with the Original Parts in the Units.

On my Day long trip to the place, I visited numerous local parts producers having Foundries and milling & CNC setups who manufacture copies of the Original Bauer Parts, including the Pistons, Con-rods, Fresh Name Plates, and what not.

These parts are sourced by the "other" Traders, and they'd replace the Originals with copies.

On Speaking with Bauer, I came to learn, such traders would buy Only the Original Casings (outer Bodies) from Bauer India, and would easily quote names of Bauer Personnel, just to lure prospective buyers sounding authentic.

They'd easily offer support on Service Requests in case anything goes wrong in future.

And sure enough, down the line a Year and Half, the buyer would be locked into viscious Maintenance & Parts replacement cycles with the Trader.

A very tell-tale sign to identify the messed-up units is, that they'd confirm if asked, whether the Machine is re-serviced/re-painted, that they've got it re-serviced themselves by their highly experienced technician.

Don't go for those machines even when You've been there and seen by Your eyes filling the Cylinders without any hiccups with these machines.

They'd usually send You the Videos with Name Plates, and Crank Case-Serial numbers/Filter-Tower Serial Numbers, filling cylinder, etc. and will have You agreed for making Pre-Payments, in Parts.

The Story Goes On, but i'd want all to know of the above traps and be wary of.

Hummm...

so here are the pictures...

After Assembly

Consider this a rookie post, I wanted to share my story that might help prospective buyers not get cheated.

And my buying experience of a pre-owned Bauer Unit.

The Unit is 2016 produced by Bauer, Germany.

It also has an Inspection Label from Dec'2020 carried out by Dolphin Middle East Marine.

This was a used unit, and per the B-Timer installed over it, it says 16hours Only.

After I replaced its cell, it read 17 hours. Does it adds up Hours Count at every Power Source Disconnection Event too (Just thinking)?

We got the Cartridge Changed since the Unit was lying idle since months.

Parts Replaced by new items:

- Safety Valves on all stages

- Pressure Maintaining Valve over the Filter Tower.

- Filling Device

Looked like that from a commercial manufacturing setup.

The Warm Greeting from them, the courtesy they displayed, and they walked us through all the other warehouses too where they had machines of very large capacities besides Breathing Compressors of over 25 cfm, Bauer Old Verticus models ranging 20+ cfm, Huge Refrigeration Compressors, Offshore Welding Equipment, and so on...

The day before, I couldn't settle and decided to clean it all the way I could reach, and opened the body frames (Pictures attached).

So this is a SIngle-Phase 240V 2.2 kW Soga make Motor badged as Bauer Part for the equipment.

To my surprise, the Power Distribution Box (Terminal Box) housing the Start and Run Capacitors, and the relays, had no dust at all in it.

The Terminal Box is some cast-aluminum body with a high density foam liner to prevent any foreign particles get into the electricals.

The Cable is also the Original one too, and just doesn't entangle.

The original Single-Phase Plug-to-Mains Connector was Cut since the Power Supply at the warehouse didn't have compatible socket, they only had for 3-phase mains.

So i got a 16A Plug and have made the connection arrangement.

For the test at the warehouse, we emptied a 6L 300 Bar Drager Cylinder, and refilled it.

The clock after we engaged the valves on Filling device and that on the cylinder, clocked 22.5 minutes to fill up to 310 Bar with 2 manual drain events from each of the drain valves.

Noise is bearable keeping it at one end of room and 10m away doesn't hurt at all.

For less than half the cost of new Junior-II like product in India (with P-11 Filters, PE-100 is available re-named as IE-100), this feels a Steal-Buy.

I verified with Bauer Facility for the Serial Number, Block Parts, commissioning details and everything they could provide non-invasively, and the Unit came out Genuine.

Today i topped-up my other Cylinder from 200 to 300 Bar, took less than 8 minutes, and the noise that the machine makes felt so soothing.

I'm worry free for don't know how many years now, for reliable Machine, this work-horse.

Sharing some pictures from cleaning it.

An important note for Buyers looking for used compressors from Bhavnagar, India (Alang Ship Wrecking Yard):

There are only a handful of Genuine Traders who will charge more than anybody else selling Breathing Compressors, but give the machine in as-is condition from how they were received by them.

The "others" (bad ones) that would quote half or 3/4 of the cost quoted by genuine traders, are all messing with the Original Parts in the Units.

On my Day long trip to the place, I visited numerous local parts producers having Foundries and milling & CNC setups who manufacture copies of the Original Bauer Parts, including the Pistons, Con-rods, Fresh Name Plates, and what not.

These parts are sourced by the "other" Traders, and they'd replace the Originals with copies.

On Speaking with Bauer, I came to learn, such traders would buy Only the Original Casings (outer Bodies) from Bauer India, and would easily quote names of Bauer Personnel, just to lure prospective buyers sounding authentic.

They'd easily offer support on Service Requests in case anything goes wrong in future.

And sure enough, down the line a Year and Half, the buyer would be locked into viscious Maintenance & Parts replacement cycles with the Trader.

A very tell-tale sign to identify the messed-up units is, that they'd confirm if asked, whether the Machine is re-serviced/re-painted, that they've got it re-serviced themselves by their highly experienced technician.

Don't go for those machines even when You've been there and seen by Your eyes filling the Cylinders without any hiccups with these machines.

They'd usually send You the Videos with Name Plates, and Crank Case-Serial numbers/Filter-Tower Serial Numbers, filling cylinder, etc. and will have You agreed for making Pre-Payments, in Parts.

The Story Goes On, but i'd want all to know of the above traps and be wary of.

Hummm...

so here are the pictures...

After Assembly