Good day.

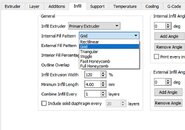

I need to print another goodman handle, even @ 70% infill I'm getting small cracks. Anyone care to make a suggestion what infill to use with PETG? I know it's stronger. I've printed with it before, just never "tools" for everyday use.

Thanks!!

I need to print another goodman handle, even @ 70% infill I'm getting small cracks. Anyone care to make a suggestion what infill to use with PETG? I know it's stronger. I've printed with it before, just never "tools" for everyday use.

Thanks!!