My ambient temperature at time of test is 30.9 Celcius.

All this time monitoring temperatures, I notice that, for every 1C increase of ambient, from 27C to 32C its +3 hotter at least on the cylinders head. When ambient hits 33C, its a nightmare.

The fear of oil being burned within the compression chamber of the compressor is real.

If I can get reading of 137C on cylinder head no 2, what do you think the internal temperature of the compression chamber would be ?

My compressor is located in a small cubicle with no direct air access at the back of the pulley fan, however I have openings on the top and on the sides and at such low air velocity of the Bauer pulley fan, those openings are decent even though not the best in my assumption. If one sees a silent type Bauer in an enclosed frame, I wonder how the air flow would be and surely my cubicle opening gives easier air flow.

30C to 34C day time ambient temp in any tropical destination is common, no matter how and where one will put a Mariner 200, because I have tested it in really shaded but open air situation, heat build up is still high if the compressor been running for 1 hour.

I wasted so much money breaking the wall on my compressor cubicle left side and making 4 of 8" pvc pipe air entry hole from the top of the cubicle roof, thinking its air flow problem..........it is not as simple as that. No matter how easy the air is around the compressor to be sucked by the pulley fan, in the end it is the perfromance of the pulley fan speed or total liters per hour. Adding fuel to fire, my P41 filter and its stand alone water separator is so huge , its causing air flow deflection from cylinder head no 2 and cylinder head no 1. My water separator and the P41 tower got warm not only because of warm air produced by the compressor but because the warm air from the pulley fan trying to cool all cooler pipes and the two cylinder head 1 & 2 was blown to it.

Now, what can you do to a compressor with a pulley fan NOT adequate for tropical application exceeding 1 hour ? Add better forced air cooling is the only solution.

I went to an automotive dyno center a while ago, in fact 3 times. They have huge fans for the car radiator and one small one for removing exhaust gas. The small one is only 750 watts ( same as my 10" axial fan ) and dang that thing is so powerful at 2,800 RPM and make so much noise. Its 14" or so and pumping 83,000 liter per minute or 3,070 CFM. Its much nosier than my Mariner too due to its massive airflow.

due to its massive airflow.

Keeping my compressor below 120C is my obsession. So I bought that 14" 3,070 CFM . It China made but should be good for at least 4,000 hours and its only US$220..

I then placed this 14" axial fan 1.5 feet on top of the Bauer at approx 45 degrees angle.

I played with the angle to get best cooling and it does shows. It is 750 watts, no bull$****, I measured 3.4 amps at 220 volt. The initial starting surge was high at 15 amps, no big deal, its induction motor behaviour of 600-700% for locked rotor current. I was thinking it would be a 1,000 watts or more because it is so much more powerful than my 10" at same wattage. The noise is very high. I do not have a db meter but its 2,800 RPM indeed high decibel.

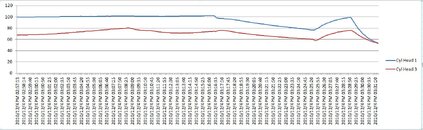

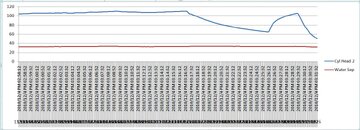

With this 14" axial blower, my P41 tower is so cool and take a look at the compressor temps reading attached. By now I have corrected the clock and one is only 1 minute slower than the other. Still the 3rd cylinder must be added by 10-15C, until I can get my wire thermo sensor into that hole Bauer prepared.

The result is amazing. I am looking forward to 33C ambient and see if my 2nd cylinder can hit 115C to 120C. For now 110C is the highest at 2nd cylinder. Looking at the excel file of the temperature reading, I can sat that at 110C for hottest cylinder which is #2, is stable because it is usually not the case at 10+ minutes compressor run without this 14" blower....it usually will creep up slowly.

Just think of an oil burning scenario in the compression chamber of any of the 3 cylinders ( 3 stage ) or perhaps 4 cylinders ( 4 stage ) compressors. Maybe if output of 200BAR / 3,000 psi from a 4 stage compressor, overall cylinder head temps will be cooler, since the compression stages is spread out more and meant more cooling pipes in between. If my compressor can hit 137C at 2nd cylinder head without forced cooling in an hour, what will happen to compressors in a tropical dive resort or any resort with 30C ambient or higher and does air fill in day time ( like me ) for 3-4 hours non stop ?

If they do not have hopcalite CO remover, in any event the compressor gets so hot and started burning oil and produced nasties, the few last tanks could have CO in them. If the nasties are not only CO, I do not know if the activated carbon can handle all of them.

Carbon built up on valves will surely occur if things get too hot. I have ripped open valves with so much soot, its scarry knowing that this is not form a car engine that does burn fuel. This soot promotes knocking in a car engine, it can do the same in a compressor by burning itself when certain temp is reached, which could be lower than a fresh compressor oil flash point....who knows.

My Mariner 200 compression stages is as follows :

Cylinder 1, ambient 1 BAR to 6-8 BAR maximum. Depending on final output pressure to tank. So here is 1 to 6-8 compression ratio with 6-7 as average.

Cylinder 2, 6-8 BAR incoming, compressed to maximum 46BAR, so its like 6 times compression ratio average

Cylinder 3, incoming 46 BAR maximum and I set final output to no higher than 217 BAR. Its 5 times compression ratio average.

Pressure readings for cylinder 1 and 2 are using digital pressure gauges of 2% accuracy with MAX pressure recording. Final pressure reading uses 1% accuracy digital gauge.

I just replaced my Bauer original gauges at the tank filling assy yesterday. One is stuck, need a finger tapping to raise pressure. The other reads 100 psi higher than actual. Total possible cycling of each pressure gauge from 3000psi to zero, is probaly only maximum 1,000 times per gauge. This is common, in 15 years of owning a few Bauers, these gauges do not live very long. Replaced with Anscroft oil fill ones.

Hope the temperatures numbers will be useful to some.

Take an IR gun, its easy to confirm, but only by data logging these temps can one see the trend in seconds increment.

Regards,

Iya

All this time monitoring temperatures, I notice that, for every 1C increase of ambient, from 27C to 32C its +3 hotter at least on the cylinders head. When ambient hits 33C, its a nightmare.

The fear of oil being burned within the compression chamber of the compressor is real.

If I can get reading of 137C on cylinder head no 2, what do you think the internal temperature of the compression chamber would be ?

My compressor is located in a small cubicle with no direct air access at the back of the pulley fan, however I have openings on the top and on the sides and at such low air velocity of the Bauer pulley fan, those openings are decent even though not the best in my assumption. If one sees a silent type Bauer in an enclosed frame, I wonder how the air flow would be and surely my cubicle opening gives easier air flow.

30C to 34C day time ambient temp in any tropical destination is common, no matter how and where one will put a Mariner 200, because I have tested it in really shaded but open air situation, heat build up is still high if the compressor been running for 1 hour.

I wasted so much money breaking the wall on my compressor cubicle left side and making 4 of 8" pvc pipe air entry hole from the top of the cubicle roof, thinking its air flow problem..........it is not as simple as that. No matter how easy the air is around the compressor to be sucked by the pulley fan, in the end it is the perfromance of the pulley fan speed or total liters per hour. Adding fuel to fire, my P41 filter and its stand alone water separator is so huge , its causing air flow deflection from cylinder head no 2 and cylinder head no 1. My water separator and the P41 tower got warm not only because of warm air produced by the compressor but because the warm air from the pulley fan trying to cool all cooler pipes and the two cylinder head 1 & 2 was blown to it.

Now, what can you do to a compressor with a pulley fan NOT adequate for tropical application exceeding 1 hour ? Add better forced air cooling is the only solution.

I went to an automotive dyno center a while ago, in fact 3 times. They have huge fans for the car radiator and one small one for removing exhaust gas. The small one is only 750 watts ( same as my 10" axial fan ) and dang that thing is so powerful at 2,800 RPM and make so much noise. Its 14" or so and pumping 83,000 liter per minute or 3,070 CFM. Its much nosier than my Mariner too

Keeping my compressor below 120C is my obsession. So I bought that 14" 3,070 CFM . It China made but should be good for at least 4,000 hours and its only US$220..

I then placed this 14" axial fan 1.5 feet on top of the Bauer at approx 45 degrees angle.

I played with the angle to get best cooling and it does shows. It is 750 watts, no bull$****, I measured 3.4 amps at 220 volt. The initial starting surge was high at 15 amps, no big deal, its induction motor behaviour of 600-700% for locked rotor current. I was thinking it would be a 1,000 watts or more because it is so much more powerful than my 10" at same wattage. The noise is very high. I do not have a db meter but its 2,800 RPM indeed high decibel.

With this 14" axial blower, my P41 tower is so cool and take a look at the compressor temps reading attached. By now I have corrected the clock and one is only 1 minute slower than the other. Still the 3rd cylinder must be added by 10-15C, until I can get my wire thermo sensor into that hole Bauer prepared.

The result is amazing. I am looking forward to 33C ambient and see if my 2nd cylinder can hit 115C to 120C. For now 110C is the highest at 2nd cylinder. Looking at the excel file of the temperature reading, I can sat that at 110C for hottest cylinder which is #2, is stable because it is usually not the case at 10+ minutes compressor run without this 14" blower....it usually will creep up slowly.

Just think of an oil burning scenario in the compression chamber of any of the 3 cylinders ( 3 stage ) or perhaps 4 cylinders ( 4 stage ) compressors. Maybe if output of 200BAR / 3,000 psi from a 4 stage compressor, overall cylinder head temps will be cooler, since the compression stages is spread out more and meant more cooling pipes in between. If my compressor can hit 137C at 2nd cylinder head without forced cooling in an hour, what will happen to compressors in a tropical dive resort or any resort with 30C ambient or higher and does air fill in day time ( like me ) for 3-4 hours non stop ?

If they do not have hopcalite CO remover, in any event the compressor gets so hot and started burning oil and produced nasties, the few last tanks could have CO in them. If the nasties are not only CO, I do not know if the activated carbon can handle all of them.

Carbon built up on valves will surely occur if things get too hot. I have ripped open valves with so much soot, its scarry knowing that this is not form a car engine that does burn fuel. This soot promotes knocking in a car engine, it can do the same in a compressor by burning itself when certain temp is reached, which could be lower than a fresh compressor oil flash point....who knows.

My Mariner 200 compression stages is as follows :

Cylinder 1, ambient 1 BAR to 6-8 BAR maximum. Depending on final output pressure to tank. So here is 1 to 6-8 compression ratio with 6-7 as average.

Cylinder 2, 6-8 BAR incoming, compressed to maximum 46BAR, so its like 6 times compression ratio average

Cylinder 3, incoming 46 BAR maximum and I set final output to no higher than 217 BAR. Its 5 times compression ratio average.

Pressure readings for cylinder 1 and 2 are using digital pressure gauges of 2% accuracy with MAX pressure recording. Final pressure reading uses 1% accuracy digital gauge.

I just replaced my Bauer original gauges at the tank filling assy yesterday. One is stuck, need a finger tapping to raise pressure. The other reads 100 psi higher than actual. Total possible cycling of each pressure gauge from 3000psi to zero, is probaly only maximum 1,000 times per gauge. This is common, in 15 years of owning a few Bauers, these gauges do not live very long. Replaced with Anscroft oil fill ones.

Hope the temperatures numbers will be useful to some.

Take an IR gun, its easy to confirm, but only by data logging these temps can one see the trend in seconds increment.

Regards,

Iya

, 8 can be read as 6...

, 8 can be read as 6...