Rich Keller

Contributor

Are SS rivets something you can get anywhere or do you go through a Marine supply place or something?

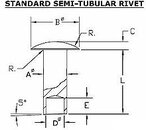

You should be able to find them in any good hardware or marine store. These are not pop rivets they are the type you put in place and widen the narrow end with a punch or an awl. There are SS washers on both sides to prevent them from pulling through. You do not need to cut into the webbing to use either type of rivet. It would be preferable to just open a hole with an awl, punch or marlin spike then put the rivet through before the hole closes up on you. Here is a better pic of the SS rivets.