Bubbletrubble

Contributor

Although it's preferable to have someone with specific knowledge on HOG regs to answer questions, it certainly isn't necessary.I wish we had a local instructor here. Doing it with someone flown in doesn't leave that support base for the inevitable questions and hands-on help someone new to reg servicing would want.

A perfectly workable solution would be to use "common sense" first, then consult the Vance Harlow book (which covers the vast majority of questions that pop into the heads of novice DIYers) and, if that doesn't solve the issue, make a post in the ScubaBoard DIY forum.

There's nothing special about HOG regs.

Troubleshooting would be conducted in the same way for other regs that share an identical design (Aqualung Legend, Zeagle, Apeks, certain Scubapro regs, etc.).

To be honest, a freely downloadable "official" reg repair manual, including up-close photos, detailed step-by-step overhaul instructions, helpful hints/warnings about pitfalls, torque specs, recommended tools, troubleshooting procedures, tuning instructions, and exploded parts diagram, would be very helpful to a novice DIYer. No need to bug an instructor, the manufacturer, or other reg repair techs when the necessary info is contained in one tidy little package accessible online to all HOG reg owners.

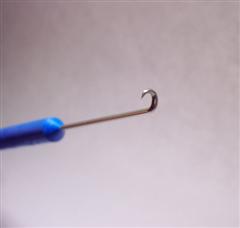

Personally, I like having 2 sets of o-ring picks: one made of stainless steel, the other made of brass. Don't know what TSandM will recommend.I was just looking at a few different O-ring picks online, and trying to decide which to buy. Can you describe which ones you liked (or what it was about them) so that I could look for them?

(Somewhere I read that someone liked Nylon/plastic over brass, but the only plastic ones I saw did not look "picky" enough.)

No need to spend a lot on them. I bought a 3-pick brass set from Dive Gear Express for $13. I like using these particular picks when I want to protect against scratching a nearby sealing surface. The pick with a ball on the end is great for gently coaxing o-rings into position during installation.

I think I spent $3 or $4 on a 5-pick stainless steel set at Harbor Freight. Similar cheap sets can be purchased on Ebay. Stainless steel picks won't bend (like the brass ones) when you exert a lot of force on them. Just be careful that you don't injure yourself -- and make sure that your tetanus vaccination is current.

I would steer clear of plastic and nylon picks for reg repair. They have a tendency to snap and break (at least the ones that I've used).

Last edited: