I am looking for a filter to add to my small compressor (140L/min) to produce OCA for personal use (occasional deco bottles with >40% O2). I looked at tower filters but they are very expensive for what I need to do here. Does anyone here know if there are "portable" personal filters I can use to filter E grade air to OCA? I envision connecting the fill whip coming from the compressor to this filter and the filter gets connected to the tank to fill it with OCA. Does this exist anywhere please?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question Filter for Compressor to Produce O2 Compatible Air for individual use

- Thread starter BoltSnap

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

admikar

Contributor

Could this help you?I am looking for a filter to add to my small compressor (140L/min) to produce OCA for personal use (occasional deco bottles with >40% O2). I looked at tower filters but they are very expensive for what I need to do here. Does anyone here know if there are "portable" personal filters I can use to filter E grade air to OCA? I envision connecting the fill whip coming from the compressor to this filter and the filter gets connected to the tank to fill it with OCA. Does this exist anywhere please?

Personal filter of inflation of diving bottle 232bar - DIVEAVENUE

Personal filter to inflate diving cylinders. Ideal Nitrox. All the accessories for the inflation of diving cylinders are at DIVEAVENUE.COM

Could this help you?

Personal filter of inflation of diving bottle 232bar - DIVEAVENUE

Personal filter to inflate diving cylinders. Ideal Nitrox. All the accessories for the inflation of diving cylinders are at DIVEAVENUE.COMwww.diveavenue.com

Thank you. I am going to contact the mfg. to see if this is what I need.

- Messages

- 20,561

- Reaction score

- 14,946

- # of dives

- I'm a Fish!

@rcontrera is the guy to ask about this thing

nuvair.com

nuvair.com

These things are not very cost effective though as the filters need to be replaced very often, they are cycled every time you fill which isn't great, they're rather big, and you MUST be filling directly from a very small compressor or you will exceed their flow rate and then there is not enough dwell time to bother. Your compressor is on the upper limits of fill rate for example so you have to be filling directly.

For the cost it really isn't that much more to add another filter to the compressor like what's linked below that would be much more economical in the long run. In that case since you're in a fairly humid area you would have your first tower filled with a drying cartridge that is replaced much more often than the filtration cartridge in second slot and would make the drying cartridge repackable. Way more cost effective.

nuvair.com

nuvair.com

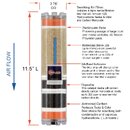

Personal Scuba Filter · DIN 300

Do you worry about air fill quality when diving? The Personal Scuba Filter mounts easily between DIN 300 tanks and the compressed air source. Produces Grade E breathing air by removing moisture, hydrocarbons, oil, taste/odor, and converts CO to less dangerous CO2.

These things are not very cost effective though as the filters need to be replaced very often, they are cycled every time you fill which isn't great, they're rather big, and you MUST be filling directly from a very small compressor or you will exceed their flow rate and then there is not enough dwell time to bother. Your compressor is on the upper limits of fill rate for example so you have to be filling directly.

For the cost it really isn't that much more to add another filter to the compressor like what's linked below that would be much more economical in the long run. In that case since you're in a fairly humid area you would have your first tower filled with a drying cartridge that is replaced much more often than the filtration cartridge in second slot and would make the drying cartridge repackable. Way more cost effective.

MCH3-MCH6 Filter Tower Add-On Kit

This filter tower add-on kit is designed for use on Coltri MCH3, MCH4, and MCH6 compressors that were purchased without filtration capabilities. This kit is comprised of OEM tubes and connectors and includes an SC000340-M filter element.

It's just what I do, so don't take it as best practice. I'm susign th followin gon a small Coltri at about 80lpm.

Rather than the beaver / Scuba Tec personal filter at the top, what I have is one like the Coltri / or Undersea UK one, which takes standard Coltri cartridges, but also it has G 1/4 fittings at either end, so I have put a female DIN fitting, then a NRV valve on the inlet and a Pressure Maintaining Valve on the exit, then a fill hose to the fill valve. This way it keeps the filter at pressure, increases the dwell time and hopefully maximises the limited filter life. The first filter at the top is just a tube with AC in it, with a couple of pads. (although you can now buy prepacked cartridges).

Rather than the beaver / Scuba Tec personal filter at the top, what I have is one like the Coltri / or Undersea UK one, which takes standard Coltri cartridges, but also it has G 1/4 fittings at either end, so I have put a female DIN fitting, then a NRV valve on the inlet and a Pressure Maintaining Valve on the exit, then a fill hose to the fill valve. This way it keeps the filter at pressure, increases the dwell time and hopefully maximises the limited filter life. The first filter at the top is just a tube with AC in it, with a couple of pads. (although you can now buy prepacked cartridges).

NICE!For the cost it really isn't that much more to add another filter to the compressor like what's linked below that would be much more economical in the long run. In that case since you're in a fairly humid area you would have your first tower filled with a drying cartridge that is replaced much more often than the filtration cartridge in second slot and would make the drying cartridge repackable. Way more cost effective.

MCH3-MCH6 Filter Tower Add-On Kit

This filter tower add-on kit is designed for use on Coltri MCH3, MCH4, and MCH6 compressors that were purchased without filtration capabilities. This kit is comprised of OEM tubes and connectors and includes an SC000340-M filter element.nuvair.com

Very similar to my project. I had a very old Bauer/Mako compressor that had a tiny OEM filter on it. I repurposed the original filter which held maybe 6 oz of AC into just a moisture trap (filled it with 13x MS), and added a 10" cartridge filter I sourced from Jim Shelden when he was in business.

I got fantastic air from it. This is smaller, so cartridge changes would be more frequent, but it likely would have been a good (and less expensive) choice... This is about 1/2-1/3 the price.

I am actually going to do this again (move this second filter over) to my new Bauer Oceanus as the OEM P0 is so small it is basically useless.

@rcontrera is the guy to ask about this thing

Personal Scuba Filter · DIN 300

Do you worry about air fill quality when diving? The Personal Scuba Filter mounts easily between DIN 300 tanks and the compressed air source. Produces Grade E breathing air by removing moisture, hydrocarbons, oil, taste/odor, and converts CO to less dangerous CO2.nuvair.com

These things are not very cost effective though as the filters need to be replaced very often, they are cycled every time you fill which isn't great, they're rather big, and you MUST be filling directly from a very small compressor or you will exceed their flow rate and then there is not enough dwell time to bother. Your compressor is on the upper limits of fill rate for example so you have to be filling directly.

For the cost it really isn't that much more to add another filter to the compressor like what's linked below that would be much more economical in the long run. In that case since you're in a fairly humid area you would have your first tower filled with a drying cartridge that is replaced much more often than the filtration cartridge in second slot and would make the drying cartridge repackable. Way more cost effective.

MCH3-MCH6 Filter Tower Add-On Kit

This filter tower add-on kit is designed for use on Coltri MCH3, MCH4, and MCH6 compressors that were purchased without filtration capabilities. This kit is comprised of OEM tubes and connectors and includes an SC000340-M filter element.nuvair.com

Is making OCA is achieved by merely adding another filter tower to the compressor with the same specs as the first filter tower in the compressor or does the OCA filter have special specs to produce OCA?

- Messages

- 20,561

- Reaction score

- 14,946

- # of dives

- I'm a Fish!

Not quite.Is making OCA is achieved by merely adding another filter tower to the compressor with the same specs as the first filter tower in the compressor or does the OCA filter have special specs to produce OCA?

In order to make OCA you have to do a few things.

First and foremost is make the air as dry as possible. This is critical because most of the nasties are going to bond with water vapor and if you can knock all of that out then the filter media is doing a lot less work. Extra mechanical dryers are the second best investment you can make on a pump with the best investment being an active chiller *basically an air conditioner for the coils though water cooling is obviously more effective, it can make filter cartridges last about 5x longer than they would otherwise*.

If you have 2x towers then the first one should be filled completely with 13x which is a desiccant since none of the other filter media work when there is moisture present.

Activated Carbon is adsorbing all of the oily bits that did not fall out in the water separators. This bit is super sensitive to moisture and is basically useless when wet and this is the part that is critical to making OCA. It will take out some of the moisture as well since Hopcalite is useless when wet.

Hopcalite is for converting CO to CO2. One will kill you a lot faster than the other and make for a really bad day when scuba diving so that one is rather critical.

The key to this whole thing is to stop the water and oil from getting to the filters in the first place. My pumps have a coalescer installed before the filter towers which holds onto the moisture and oil, provides more dwell time for the gas to cool off which helps more of it coalesce and greatly improves filter life. I think Lawrence Factor still sells coalescer inserts for some of their towers and this is a great option if you can swing it. If you have a coalescer then a normal "breathing air" filter that has all of the things above in it should give you OCA without issue and do it for a very long time.

If you don't have a coalescer then what the second tower does is allows you to rebalance the ingredients to what your specific compressor needs. Libya has a weird ass climate so your needs in a hot as hell but super dry summer are probably different than what your needs are in the winter when it is very wet. It's all about the dew point of the gas coming into the pump and how well it can knock the dew point down. You may find in the winter that you need the first tower filled with nothing but 13x and the second tower to have a normal breathing air filter in it that includes 13x to give you extra drying capacity before the AC bed gets wet. In the summer though you may keep the first tower as 13x only and then the second one only has Hopcalite and Activated Carbon in it.

In an ideal albeit expensive world you have 4x towers and you change each filter independently of the others based on your specific usage of Coalescer, 13x, AC, Hopcalite. This is admittedly what I use on my personal pump but I do not have liability tied to a commercial fill station. I'm an engineer so part of it is the challenge of figuring out the specific intervals to change to maximize filter life but if I did have the liability of a commercial fill station I would use a LF tower and change on whatever CF limit they have to cover my butt.

I added a filter tower from American Airworks... came with the filter. Was ~ $420 and then a few BSPP fittings to get it to 1/4" to connect it up. I got the 21" model but they make a smaller one as well.

Has worked great. If I remember it was good for 16,000cf @ 70F or something like that. Filters are $60 / filter.

Has worked great. If I remember it was good for 16,000cf @ 70F or something like that. Filters are $60 / filter.

Attachments

Similar threads

- Replies

- 15

- Views

- 1,848

- Replies

- 4

- Views

- 1,496

- Replies

- 14

- Views

- 1,088

- Replies

- 40

- Views

- 3,781

- Replies

- 17

- Views

- 1,506