The Chairman

Chairman of the Board

The trim is mostly done and it looks great.

There's still a few pieces missing, and that means I have to rip a few more boards and have at it. I'm thinking of doing the white HDF in the doors as well and staining the exposed wood to match. It looks so sad compared to the rest of the shop.

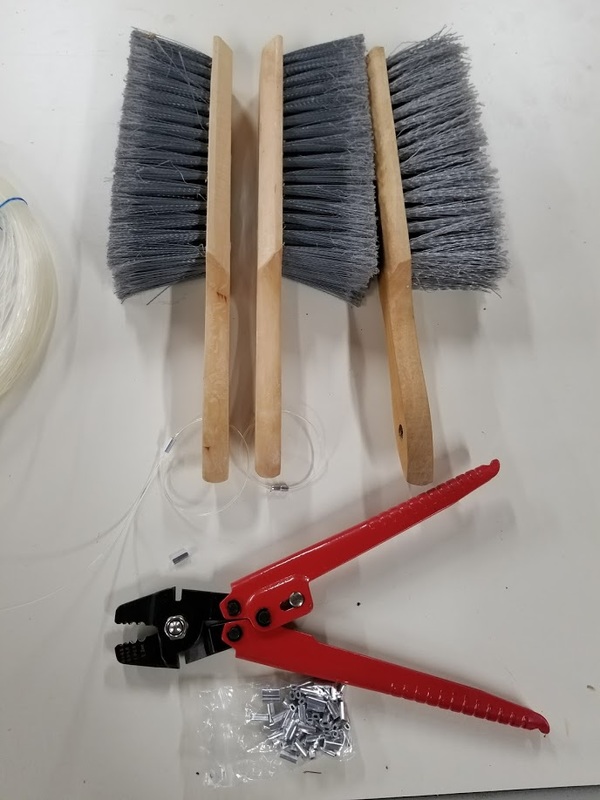

This also means that I have hours of organizing to do. Things like adding mono rings to brushes so they can be easily hung on a cup hook.

Dan and his daughter came for the weekend and got to enjoy the fire ring! The photos are uploading, so I'll post them later.

There's still a few pieces missing, and that means I have to rip a few more boards and have at it. I'm thinking of doing the white HDF in the doors as well and staining the exposed wood to match. It looks so sad compared to the rest of the shop.

This also means that I have hours of organizing to do. Things like adding mono rings to brushes so they can be easily hung on a cup hook.

Dan and his daughter came for the weekend and got to enjoy the fire ring! The photos are uploading, so I'll post them later.